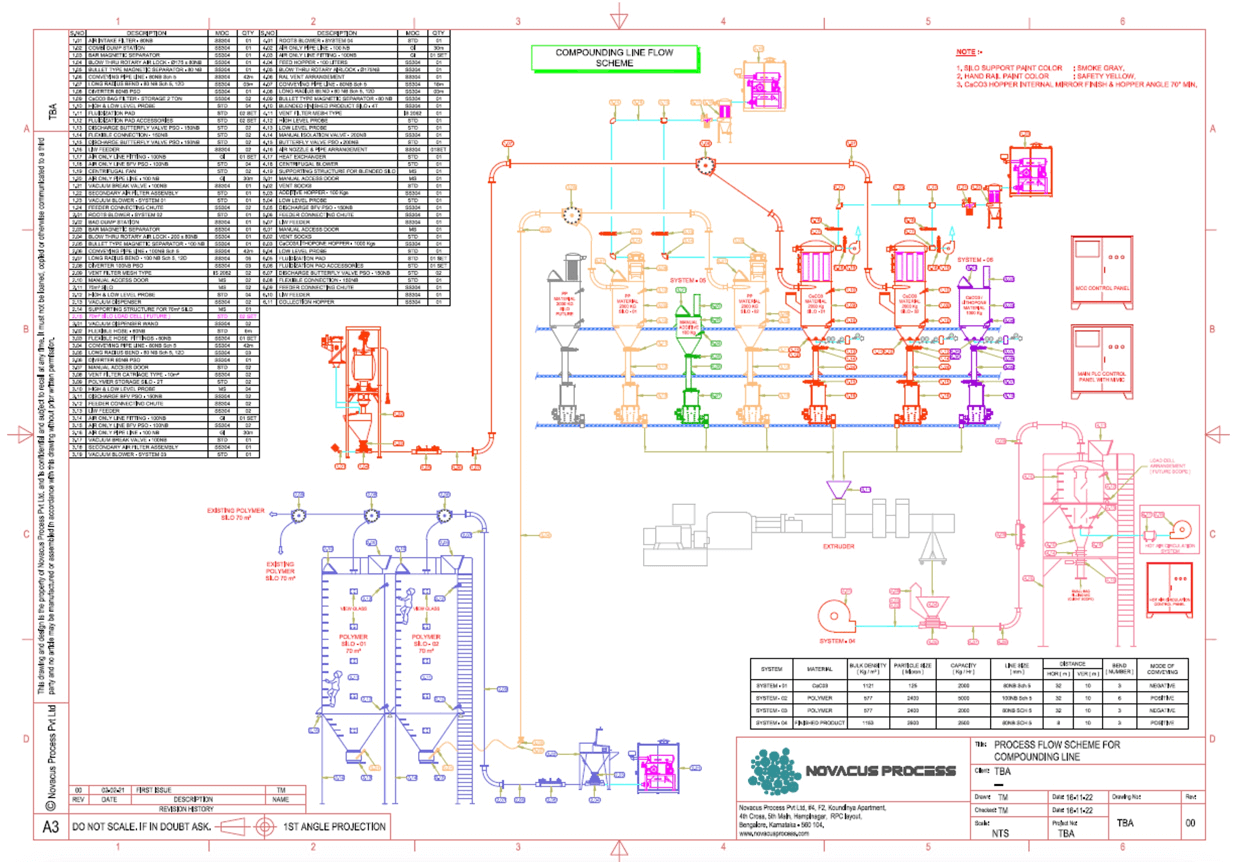

INGREDIENTS HANDLING SYSTEM

Novacus Process specializes in handling multiple ingredients for bakery process, using Lean phase pneumatic conveying systems of both vacuum & positive pressure conveying system.

At Novacus Process, we offer batching system and other automated solutions for Food / Plastics / Chemical / Steel / Cement Industries.

Our system designs include all forms of powder materials coming from bulk tankers, big bag/Jumbo bag and small bags transferring to bulk storage silos or directly to batch hopper.

Starting from raw materials delivery through Bulk tankers / Big bag dischargers / bag dump stations, material is pneumatically conveyed by a positive pressure blower into storage silos and then using our special design Rotary airlock valves material is conveyed onto the batch hoppers above mixers. Finally, accurately maintaining feeding time & material into the mixers.

KEY COMPONENTS

- Positive blower / Vacuum Pump

- Bag Dump Station / Jumbo Bag Discharger

- Blow / drop thru Rotary air locks

- Long radius bend

- Diverters

- Pressure relief valve

- Vent filter

- Flow aid arrangement (bin activator / fluidization pads / pneumatic knockers)

- Inline sifters / Vibro Sifters

- LIW arrangements

- Silo’s / batch hoppers

- Flexible connections

- Safety valves

- Explosion production if applicable

- PLC automation system