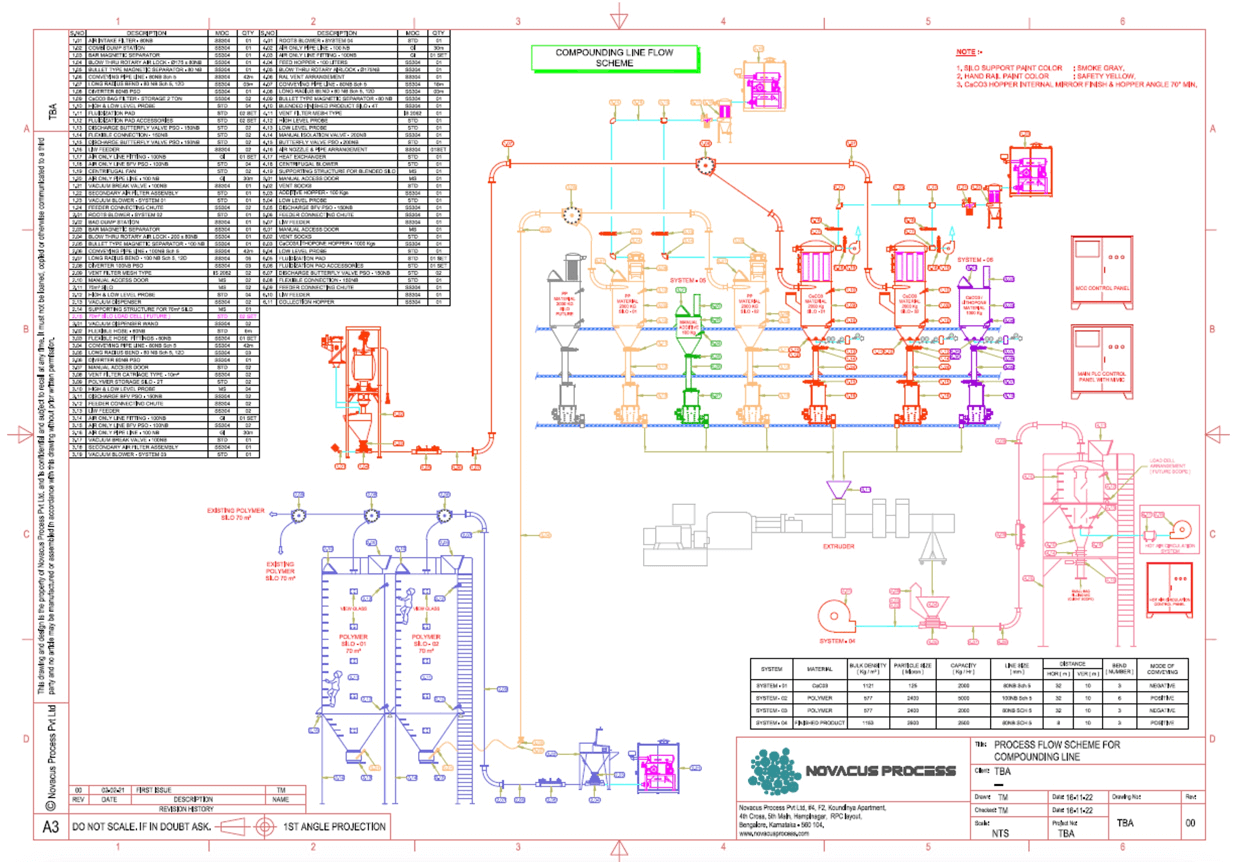

COMPOUNDING FLOW SCHEME

Novacus Process offers solutions for plastic compounding including bulk bag unloading systems, raw material storage & feeding through conveying.

We design and configure bulk material systems for pressure or vacuum lean phase or dense phase conveying.

Right from simple vacuum systems to centralized plastics conveying systems, Novacus Process provides customized solutions engineered to your requirements.

For compounding process raw material is delivered through big bag dischargers/tipping stations/Bulk tankers. Material is then pneumatically conveyed by a positive pressure blower into storage silos and then using negative pressure raw material is conveyed from silos onto the storage hoppers above extruders. Finally, accurately feeding the material from hoppers into the extruder through Loss-in weight feeder

KEY COMPONENTS

- Positive blower / Vacuum Pump

- Bag Dump Station / Jumbo Bag Discharger

- Blow / drop thru Rotary air locks

- Long radius bend

- Diverters

- Pressure relief valve

- Vent filter

- Flow aid arrangement (bin activator / fluidization pads / pneumatic knockers)

- Inline sifters / Vibro Sifters

- LIW arrangements

- Silo’s / batch hoppers

- Flexible connections

- Safety valves

- Explosion production if applicable

- PLC automation system