DENSE PHASE SYSTEM

Dense phase pneumatic conveying is a process for moving material and is used across a variety of light and heavy industries. It transports materials through enclosed pipelines, from one silo to the next; carefully moving the material, along the bottom of the pipeline, using high pressure and low gas volumes.

This form of pneumatic dense phase conveying ensures there is no damage to the material and thereby, provides lower wear on the conveying system.

Right from simple vacuum systems to centralized plastics conveying systems, Novacus Process provides customized solutions engineered to your requirements.

ADVANTAGES

- Lower conveying velocity, typically 2 - 10 m/sec results in much reduced pipe wear.

- Can handle a wide range of materials both wet and dry

- Conveying pipe work is generally smaller than lean/medium phase systems

- Power consumption is low and usually directly proportional to the actual transfer rate

- Ancillary equipment e.g., Filters are generally smaller

- Fewer moving parts than rotary valves or screw pump systems

Density Stabilisers - Some materials do not form stable “plugs”. These are those that are not “air retentive” or “not permeable”. If conveyed at low velocity these materials generate large friction forces that lead to a blockage.

Density Stabilisers - Introduces a small amount of the conveying air at regular intervals along the conveying pipeline. This breaks up the material “plugs” into shorter lengths and ensures smoother conveying at lower velocities.

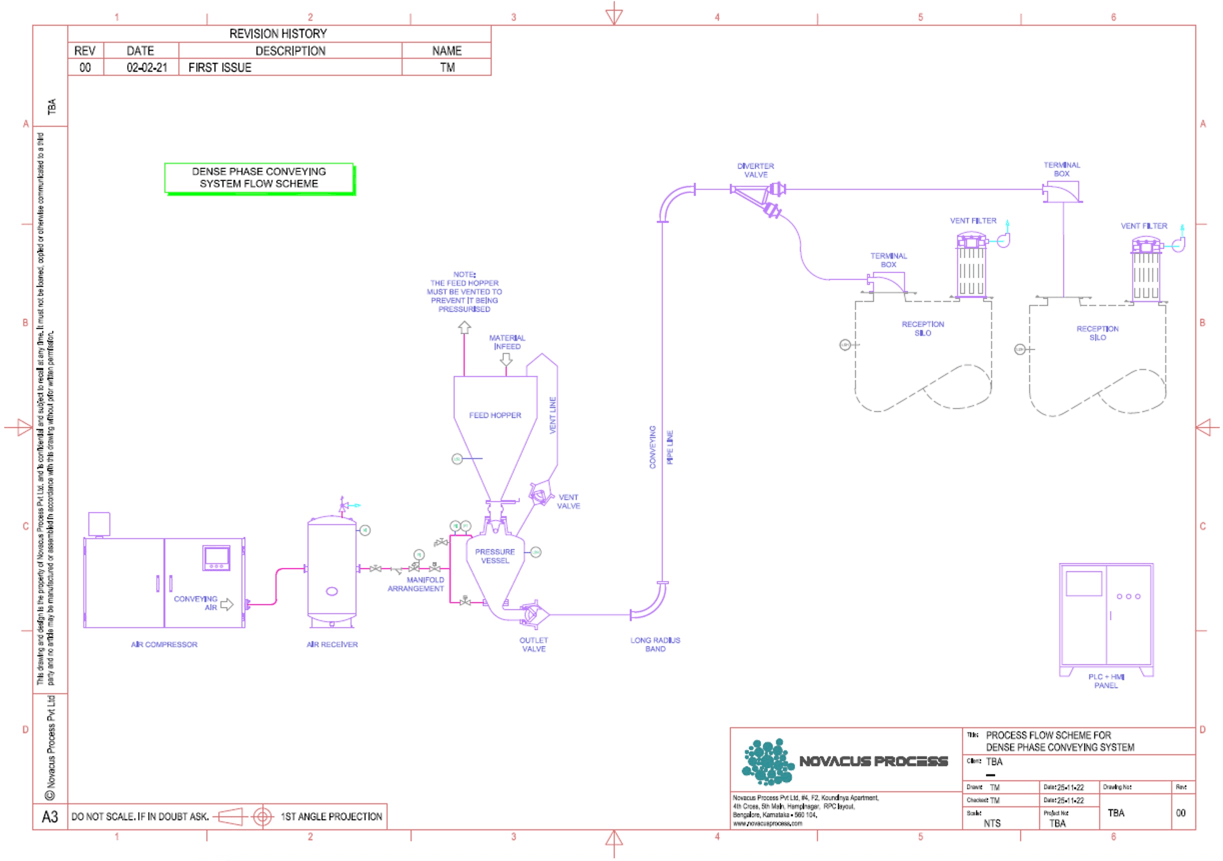

KEY COMPONENTS

- Screw Compressor

- Air Receiver

- Feed Hopper

- Vessel Assembly

- Conveying Pipeline

- Long Radius Bend

- Diverter Valve

- Terminal Box

- Vent Filter

- Plc Control System

VESSEL ASSEMBLY - KEY COMPONENTS

- Manual Isolation Valve

- Flexible Connection

- Inlet Novarc Valve

- Pressure Vessel

- Vent Valve

- Manifold Assembly

- Outlet Bend

- Outlet Novarc Valve