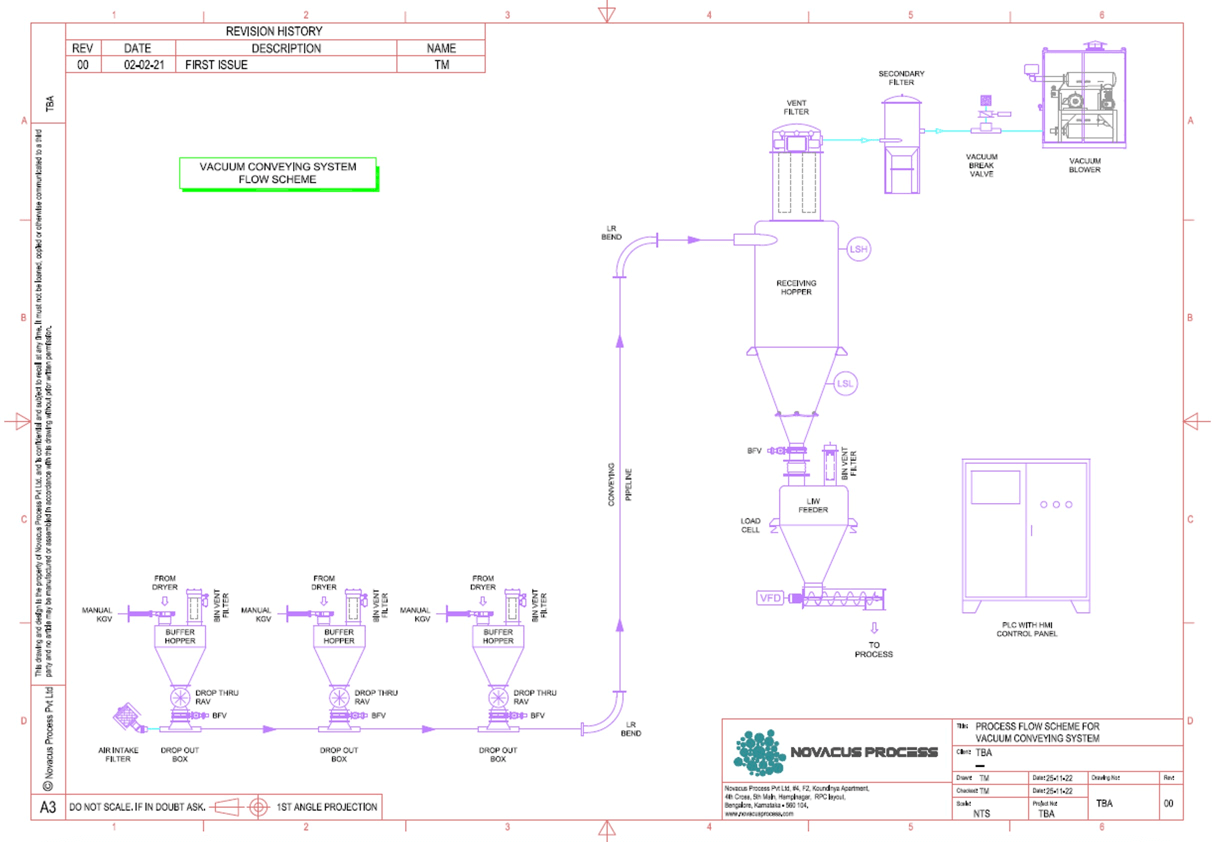

VACUUM CONVEYING SYSTEM

Vacuum conveying system is suitable for very fine product to avoid line buildup, generally used in batching system and easy to switch over multiple systems. Vacuum Conveying is the method of transferring powders/granules from one place to another within a processing area using negative pressure.

For multiple feeding points and transferring into common hopper / silo, the vacuum system will be perfect choice, since this system will avoid air leakage from airlocks and lesser pressure drop.

There are two types of vacuum conveying: dilute phase mode and dense phase mode.

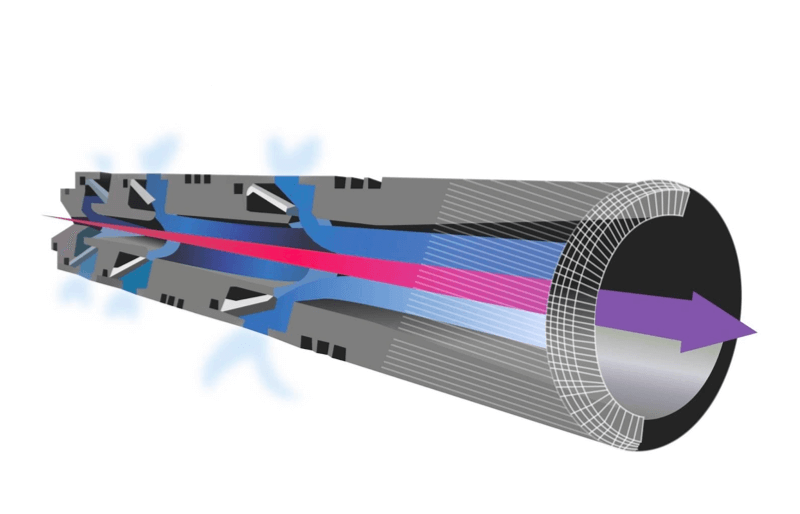

In Vacuum Lean Phase Conveying, the product is conveyed within the air stream at a very high velocity. This method of transfer is suitable if there is no concern of segregation within the product.

Vacuum Dense Phase Conveying transfers the product in slugs within the pipeline at slower velocity. This type of conveying ensures there is de-mixing of product material and suitable for transferring friable or blended product material.

ADVANTAGES

- Dust-free & contained transfer of material

- Suitable for conveying Friable or blended product materials

- Vacuum Conveying Systems are highly reliable

- Low maintenance and easily cleaned

- Smaller footprint for the system

- Works extremely well for transfer Toxic/explosive product material

KEY COMPONENTS

- Vacuum Pump

- Bag Dump Station / Feed Hopper

- Blow / drop thru Rotary air locks

- Long radius bend

- Diverters

- Vent filter / Secondary filter

- Flow aid arrangement (bin activator / fluidization pads / pneumatic knockers)

- LIW arrangements

- Silo’s / batch hoppers

- Flexible connections

- Safety valves

- PLC automation system